The Makerspace has (3) Dremel 200 Series that are available for use. This page is a guide for using the Dremel 200s. There is no workshop required to work with these tools.

Getting Started:

Operating a Dremel 200.

To attach a new bit to the Dremel, press the small silver button while twisting the housing clockwise. The opposite will lock a new bit into place.

Once plugged in, moving the blue switch to the middle turns the Dremel on at 15,000-rpm setting and moving the switch to the end turns on the 30,000-rpm setting.

Attaching different tips to the Mandrel requires twisting the screw end into the bit. To use different attachments with the Rotary Tool Mandrel, unscrew the top and insert the attachment between the screw and body, tightly securing the screw back on.

Do not forgot safety glasses and gloves!

|

Carving Bit Carving and Engraving. |

|

Mandrel Used in junction with polishing bits. |

|

Rotary Tool Mandrel Used in junction with cutting wheels. |

|

407 Sanding Band Used for shaping or smoothing. |

|

408 Sanding Band Used for shaping and smoothing as well as removing rust. |

|

Cut-off Wheel Used with the mandrel bit to cut. Only cuts along the edge. |

|

Felt Polishing Cone Used for polishing, creating a smooth finish. Can be used with or without Polishing compound. |

|

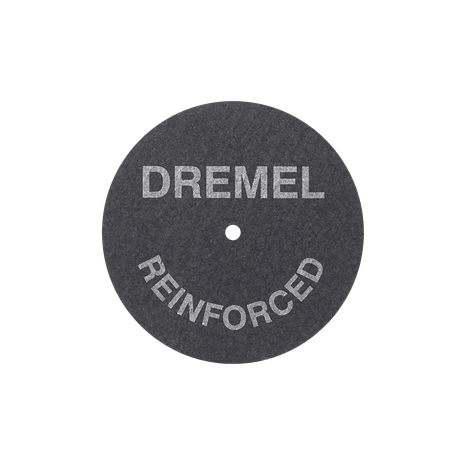

Fiberglass Reinforced Cut-off Wheel Used for cutting, creating grooves, and trimming. |

|

Felt Polishing Wheel Used for polishing, creating a smooth finish. Can be used with or without Polishing compound. |

|

432 Sanding Band Used for shaping and smoothing as well as removing rust. |

|

Aluminum Oxide Grinding Stone Used for sharpening, deburring, and grinding. |

|

Aluminum Oxide Grinding Stone Used for sharpening, deburring, and grinding. |

|

Silicon Carbide Grinding Stone Used for sharpening, etching, and grinding on conic and flat surfaces. |

© Coastal Carolina University | P.O. Box 261954, Conway, SC 29528-6054 USA | +1 843-347-3161